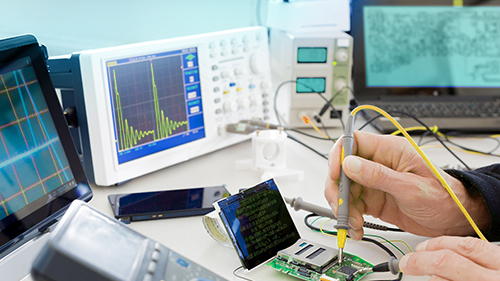

System designers have been working to improve the degree of integration to their systems ensuring quality and reliability. Automated test equipment (ATE) plays a vital role in this process by enabling comprehensive testing and validation of integrated circuits (ICs), semiconductors, and other electronic devices. As the functionality of large-scale integrated circuits increases there is a growing need for more advanced testing solutions that can keep pace with the demands of the industry. The traditional ATE system employs a separate pin electronics module to handle signal routing and measurements between the tester and the device under test (DUT). to address these limitations, the integration of pin electronics directly into the ATE system has emerged as a promising solution.

What is an integrated pin electronics system?

The latest Automated Test Equipment (ATE) comes with an integrated pin electronics system. The pin electronics are responsible for managing the signal routing, measurement, and control between the ATE tester and the DUT. traditionally the pin electronics were required to be connected using separate modules or cards through cables and connectors. The integration of the electronics driver into the system allows for a more compact and streamlined testing setup, eliminating the need for an external pin electronics module and associated interconnects.

Functions of an Integrated Pin Electronics system:-

-

Signal routing:

The ATE Pin electronics manages the routing of signals between the ATE and DUT. it controls the connections between the tester channels and the corresponding pins on the testing unit, enabling the transmission of signals for testing purposes.

-

Signal switching:

In order to execute various test configurations, apply stimulus signals, and capture response signals during the testing process we need an electronic driver. The pin electronics manage to smoothly switch between the analog and digital signals on different pins on the DUT and tester channels to facilitate the execution of these tests.

-

Measurement and control:

The system performs measurements of voltage, current, frequency, and other relevant parameters at the DUT’s pins. This enables characterization and validation of the device’s performance and ensures compliance with specified requirements. Additionally, it provides control signals to the DUT for configuring its internal circuitry or initiating specific test sequences.

-

Impedance management:

In order to maintain accurate and reliable signal transmission during testing the system ensures proper impedance matching between the tester channels and the DUT pins to minimize signal reflections, distortions, and crosstalks.

-

Test mode configuration and data acquisition:

This advanced system provides accurate configuration for different test modes and settings based on the testing unit requirements. This facilitates the selection of appropriate voltage, frequency, and other parameters necessary for execution. The system is also responsible for acquiring response signals from the DUT during the test. These signals are then analyzed to determine the device’s performance and compliance with specifications.

Advantages of the ATE Pin electronics:-

By integrating pin electronics into the ATE system in products like Venus4(ISL55161), Jupiter, Mercury, Vesuvius, etc, several advantages are realized. These include

- improved signal integrity due to reduced signal path lengths and minimized signal distortion,

- faster switching between test modes and configurations,

- Increased flexibility to accommodate diverse devices with varying pin counts and test requirements,

- And integrated pin electronics contribute to improving overall testing efficiency by reducing test setup time, increasing throughput, and enhancing measurement accuracy.

The Integrated pin electronics system represents a significant advancement in electronic testing. By eliminating the need for larger and more complex setups it has made the process of testing simpler and faster. It is a robust solution to meet the evolving demands of comprehensive testing and ensure the quality and reliability of electronic components.